04. Laser cutting What is laser?

It's not sci-fi. Laser technology has been used for many years in the production of plastic products.

It is extremely accurate, fast and efficient. What are the benefits of laser cutting plastic and what products are made using this technology?

How does the laser get you in shape?

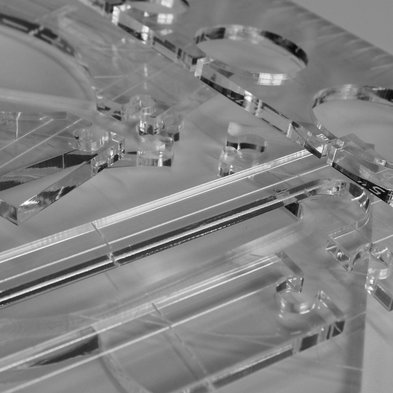

Laser cutting is a perfect non-contact technology and there is no dust when using the laser. Thanks to these laser cutting functions, even complicated shapes can be cut out of the plastic and there is no need for further processing. The cut will be perfectly smooth.

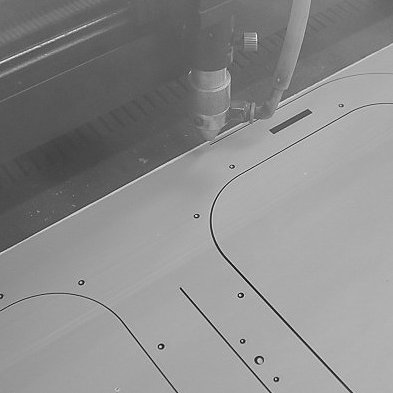

The laser has a minimal thermal effect on the material and is therefore suitable for both 2D and 3D applications. For cutting, processing and engraving plastic we use CO2 laser, which is also known as Eurolaser.

Our laser can cut materials up to a thickness of 10 mm with a large active area of 2000 x 1300 mm.

Why acrylic / Plexiglas?

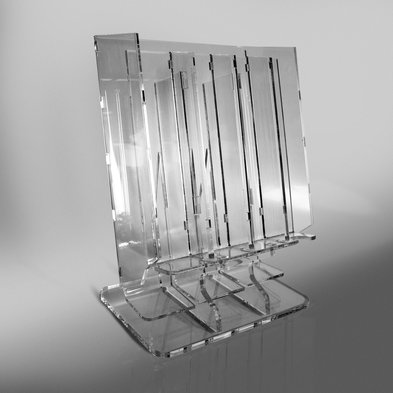

It is a particularly suitable material. Both types are suitable for laser cutting and engraving - extruded and cast acrylic. After cutting, this material remains clear and clean, the edges are sharp and no further polishing is required. We are able to process all standard and large formats.

What we cut most often with the laser?

The possibilities of cutting with the laser are very large for plastics. The laser is able to handle both large format products and small details. It is therefore also suitable for cutting and engraving. When combined with backlighting and other technologies, it can provide truly unique solutions.